2016: The Year in Innovation

- Friday, December 23rd, 2016

- Share this article:

At Mobile Marketing were proud to help tech companies showcase their cutting-edge solutions, whether its on our website, in our magazine or at our Mobile Marketing Summits. Giving a platform to companies that are breaking new ground in their market brings audiences one step closer to the ideas and developments that will shape tomorrow.

In that spirit, our Innovation Lab feature takes a step beyond the world of apps, ads and handsets with slightly bigger screens, in order to share some of the tech worlds innovative ideas. Now, at the end of the year, we take a look back at the best Innovation Lab stories of 2016, and the trends that dominated this year in technology.

Robotics

Advancements in robotics made in the past decade mean that were beginning to see consumer-grade robots that live up to the potential of the technology, especially when combined with similar leaps forward in AI and machine-learning software. Robotics is a wide-ranging discipline, and this year has seen innovation in everything from swarm-style robots designed for enterprise to microscope biological devices that can move through the human body making repairs.

Boston Dynamics Unveils Robot Giraffe

Google-owned robotics experts Boston Dynamics have revealed their latest design, a smaller version of its Spot bot fitted with an extendable arm that makes it resemble a bizarre robotic cross between a dog, a giraffe and a dinosaur.

The SpotMini weighs only 65lbs, or 55lbs without the arm attachment, and abandons the hydraulics of the larger model for electric motors that can run for around 90 minutes before needing to recharge.

The robot comes packed with a variety of sensors, including depth cameras and a solid state gyroscope that enables it to move its body around while keeping the robotic arm static in one position. The SpotMini also has proprioception sensors in each limb, enabling it to maintain its balance when many other robots would tumble, and navigate stairs with reasonable ease.

The team at Boston Dynamics have clearly put the robot through its paces, with the released video showing the SpotMini sorting dishes and recycling, navigating under tables and slipping on banana peels before righting itself.

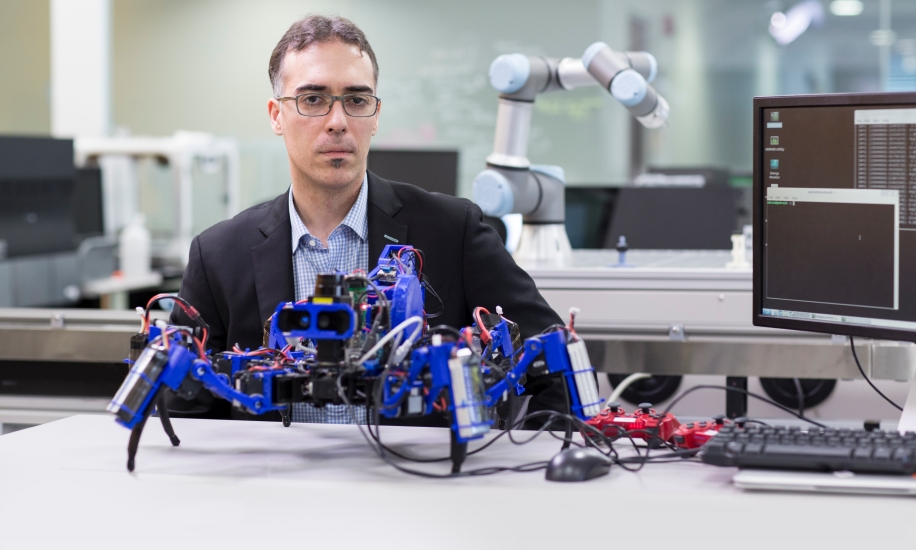

Siemens Deploys Army of Team-working Robot Spiders

If walking into your workplace to find it overrun with a horde of robotic spiders that are working together to solve problems and carry out their objective sounds like the kind of nightmare youd have after too much cheese, be thankful you dont work in one of Siemens plants in New Jersey, where thats exactly what researchers are working on.

The Siemens Spiders, or SiSpis, have been designed to make it easier to repurpose existing factories for automation, and can work together to 3D print structures and parts in real time. The robots can also be easily reprogrammed to carry out other tasks, a versatility that distinguishes them from many other industrial robots and could make them incredibly useful.

Rather than installing expensive robots that can only perform one or two tasks well, the SiSpis can theoretically take on a wide range of tasks, depending on whats most important at any given time. The robots have onboard cameras and laser scanners that interpret their environment, and ensure that together they can cover complex designs with their 3D-printer arms.

The robots also have a degree of autonomy, and are capable of making their way back to their charging station when running low on power, and handing off their current task to another spider within the system. The bots communicate using Bluetooth and wi-fi to create a hivemind that means tasks are always tackled in the most efficient way.

Origami Robot Unfolds in Your Stomach to Carry Out Surgery

If youre unlucky enough to swallow a battery in the next couple of years, you could find yourself also swallowing a tiny robot to help get it out before it does any damage, thanks to a new device created by researchers from MIT, the University of Sheffield and the Tokyo Institute of Technology.

The robot in question has a frame made of dried pig intestine that is designed to be eventually dissolved by your own stomach acid, and is folded up and encased in ice so it can be swallowed. Inside the stomach, it unfolds and can be manipulated using magnetic fields to pick up foreign objects stuck inside your stomach.

“Its really exciting to see our small origami robots doing something with potential important applications to health care,” said Daniela Rus, the lead researcher on the project. “For applications inside the body, we need a small, controllable, untethered robot system. Its really difficult to control and place a robot inside the body if the robot is attached to a tether.”

“This concept is both highly creative and highly practical, and it addresses a clinical need in an elegant way,” said Bradley Nelson, professor of robotics at the Swiss Federal Institute of Technology, Zurich. “It is one of the most convincing applications of origami robots that I have seen.”

Healthcare

Medicine and healthcare has always helped drive innovation, and were seeing increasing cross-overs between the realm of health technology and other disciplines like robotics, nanotechnology and even the world of mobile. The quantified self trend is enabling consumers to monitor their health and fitness closer than ever, and providing medical professionals with a more complete look at patients before, during and after procedures.

Man Lives for 555 Days on Heart in a Backpack

Stan Larkin, a 25-year-old from Michigan, is celebrating a successful full heart transplant, an event that would be notable enough, but is made all the more incredible by the fact that his original heart was removed over a year and a half ago.

Stan and his brother Dominique were both diagnosed with familial cardiomyopathy, a genetic heart condition that can cause heart failure with no warning. After years on the donor waiting list, both siblings had their hearts removed and were fitted with an artificial heart device called a Syncardia.

“They were both very, very ill when we first met them in our intensive care units,” said Dr Jonathan Haft, associate professor of cardiac surgery at the University of Michigan Frankel Cardiovascular Center. “We wanted to get them heart transplants, but we didnt think we had enough time. Theres just something about their unique anatomic situation where other technology wasnt going to work.”

While Dominique only needed to use the technology for a few weeks before receiving a full transplant, Stan spent more than a year on the waiting list. So he could leave the hospital and maintain a normal life, he was equipped with a 6kg portable device that connected to his vascular system to keep oxygenated blood pumping around his body, which he wore in a backpack.

Thought Control Used to Activate Drug-releasing Nanobots

Thought Control Used to Activate Drug-releasing Nanobots

In what appears to be an attempt to cram as many future-tech concepts into a single experiment as possible, Israeli researchers have used thought waves to remotely control a series of drug-dispensing nanobots inside a living locust.

As detailed in academic journal Plos One, the nanobots consisted of folded DNA which opened up when heated, releasing a glowing chemical. These were placed in metal coils connected to a power source that would produce heat, and then injected into locusts.

The researchers then used EEG helmets to record the electrical activity in their brains, with machine learning software tracking when they hit a certain level of activity, which in turn triggered the nanobots heating up and releasing their payload.

The whole project serves as a proof of concept step towards using similar technology on humans to deliver drugs that can activate based on certain brain patterns. The technology could help patients with severe communication issues to control their dosage, or even aid in mental health treatment.

Bionic Fingertip Lets Amputee Feel Textures

While the last few years have seen leaps and bounds made in the space of prosthetic design thanks to innovations in 3D printing and engineering processes, one of the most difficult things to recreate in a prosthetic is the sense of touch that would accompany interactions and serve as valuable feedback.

Researchers at the École Polytechnique Fédérale de Lausanne in Switzerland have made a huge leap forward on that front with an artificial fingertip that connects to nerves in the patients upper arm, and enables them to distinguish between different textures.

“The stimulation felt almost like what I would feel with my hand,” said Dennis Aabo Sørensen, the amputee who worked with the scientists who develop the system. “I still feel my missing hand, it is always clenched in a fist. I felt the texture sensation at the tip of the index finger of my phantom hand.”

The development makes Sørensen the first person in the world to recognise textures using a bionic sensor. Thanks to the sensor and electrodes that were surgically implanted into his arm, he was able to distinguish between rough and smooth surfaces with 95 per cent accuracy.

3D Printing

Some of the previous stories have already mentioned 3D printing, and its no surprise. This revolutionary technology has helped to make manufacturing and engineering easier and cheaper, with innovators able to create tools and components that were previously unimaginable, or prototype creations at a fraction of the previous cost. 3D printing is an extraordinary technology in its own right, and its also powering a new generation of creators to help achieve their visions.

Brazilian Vets 3D Print Goose Beaks and Tortoise Shells

Brazilian Vets 3D Print Goose Beaks and Tortoise Shells

A group of veterinarians, dental surgeons and 3D designers who have dubbed themselves the Animal Avengers have been making a name for themselves in São Paulo by creating cutting-edge prosthetics for injured animals, from a tortoise whose shell was damaged in a fire to a Brazilian goose with an injured beak.

Victoria the goose is the organisations latest success story, and their most challenging design yet. The animal was discovered off the coast of Brazil in 2015 with a large part of her beak missing. Marine environmental nonprofit Friends of the Sea cared for her, but with the bird struggling to eat or drink, they called in the expertise of the Animal Avengers.

Victoria received her first replacement beak in late 2015 following 3D scanning of her injuries. While the initial beak lasted for around five months, it eventually proved too heavy for the bird, and began to drop down from where it had been fixed.

Thankfully, the team behind the prosthetic were able to use their initial scans and what theyd learned since to create a much more elegant design that was only a third the size of the first, but still enabled Victoria to live a normal life.

International Space Station Puts Low-Gravity 3D Printer to Use

International Space Station Puts Low-Gravity 3D Printer to Use

3D printing has a whole range of uses, but giving astronauts aboard the International Space Station the ability to produce the tools and parts they need as and when they need them may be one of the most extraordinary.

The Additive Manufacturing Facility (AMF) is the second 3D printer set up aboard the ISS, and is considerably more advanced than the first. NASA recently used the device for the first time, creating a wrench that will enable astronauts to carry out vital maintenance work, complete with special fastening clip designed to stop it drifting away in zero gravity.

The printer was created by Made In Space, a California-based company that designed a way of making use of 3D printing technology in zero-g following a multi-year collaboration with NASA. The printer had to be designed with special safety considerations, had to be reliable enough to work for long periods of time in space, and needed to be able to survive its rocket launch to the ISS.

The printers bed is only around 4″ by 6″, but the AMF already has a print queue of around six months worth of parts and projects to attend to, demonstrating how important having a reliable way of manufacturing tools about the ISS is, and the potential savings that the AMF could drive by reducing the need for expensive launches carrying equipment.

Researchers 3D Print Hydraulic Robots That Walk Off Printer

Researchers at MITs Computer Science and Artificial Intelligence Lab (CSAIL) have developed the first-ever technique for 3D printing devices with both solid and liquid materials at the same time, resulting in robots that require almost no assembly to be fully functional.

“Our approach, which we call printable hydraulics, is a step towards the rapid fabrication of functional machines,” said Daniela Rus, director of CSAIL. “All you have to do is stick in a battery and motor, and you have a robot that can practically walk right out of the printer.”

To demonstrate the concept, the researchers have 3D printed a small six-legged robot that can move using 12 hydraulic pumps embedded within its body, as well as components for other existing machines like a soft rubber hand for the labs research robot.

“Building robots doesnt have to be as time-consuming and labour-intensive as its been in the past,” said Rus. “3D printing offers a way forward, allowing us to automatically produce complex, functional, hydraulically-powered robots that can be put to immediate use.”

Large-scale Projects

Most of our stories so far have been about small-scale advancements in technology; prototypes, pilot schemes and experiments aimed at extending the bleeding edge of what we can do on an individual basis. But innovation can also have a wide-ranging impact when put to work in the world and society around us, from tackling pollution to dealing with widespread health problems. This section takes a look at technology that aims to make large-scale changes to the world and improve life for everyone.

Connected Pigeons Will Track London Air Quality

Plume Labs, a tech firm that helps the public track and reduce their exposure to air pollution, has launched a flock of pollution-monitoring pigeons in London that will help monitor pollution levels using specially designed backpacks.

The initiative, created in partnership with marketing and technology agency DigitasLBi, aims to raise awareness of air quality in the capital, and will see ten birds released over the course of three days to form the Pigeon Air Patrol.

The pigeons are fitted with lightweight pollution sensors that are stitched onto small fabric vests that fit comfortably onto the pigeons and will measure levels of nitrogen dioxide and ozone, the two main gases behind harmful air pollution in built-up areas. Londoners will be able to tweet their location to @PigeonAir to receive an instant response from one of the pigeons, telling them about the level of pollution in the area.

“Air pollution isnt sexy and people dont engage with it,” said Pierre Duquesnoy, creative director at DigitasLBi. “So the heart of our idea was to make air pollution more accessible and relevant to people. The Pigeon Air Patrol is a perfect example of how data combined with creative storytelling can raise awareness of a serious health and environmental issue.”

Billboard Entraps Mosquitoes by Mimicking Human Sweat

With the Zika virus outbreak in South America declared an international public health emergency, searching for ways to control mosquito populations have never been more important, and two ad agencies in Brazil have come up with a unique way to trap and kill the pests.

Posterscope and NBS have created a special billboard that emits a solution of lactic acid and carbon dioxide that mimics human sweat and breath, attracting and trapping mosquitoes within the billboard where they eventually die from dehydration. The billboards, which also utilise UV light to draw in the insects, can attract Aedes aegypti, the species that carries the Zika virus, from up to 1.5 miles away.

Two of the billboards have been installed in Rio de Janeiro, and the companies have released the design online under the Creative Commons license, enabling other companies and cities to create their own. The billboards cost around $500 (£350), and so could prove a relatively cheap solution to helpin